All about Caster Manufacturer

Wiki Article

Casters Supplier - The Facts

Table of ContentsNot known Details About Casters Supplier Getting My Caster China To Work7 Simple Techniques For Caster Wheel ManufacturerCaster China Things To Know Before You Get This

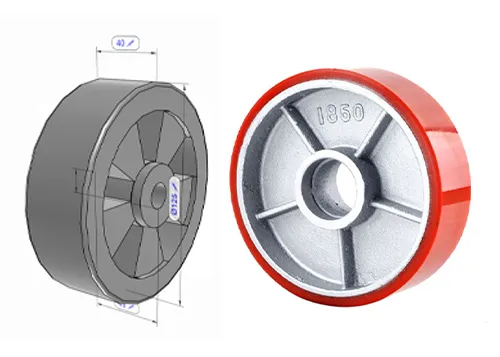

Selection as well as usage of top quality sliver canisters is indispensable for the manufacturing of great yarns. Leading mills across the world understand this as well as that's exactly why the need for customised HDPE is climbing significantly. Considered that the performance guarantee of these containers are originated from its elements, purchasers are increasingly trying to find suppliers that provide end-to-end bit managing options.Unlike what numerous believed earlier, casters are a lot more than just wheels. Specialist wheel wheels for rotating cans include the install along with the wheel itself and they make certain smooth sliver transport (and top quality stability) in the mill floorings. Casters with various physical specifications (dimensions, forms, and so on) are readily available for the numerous sorts of bit canisters made use of in the rotating process.

The casters you select require to have the integrated ability to fulfill the precise requirements. Some typically used caster wheel materials are: Wheel wheels made with polypropylene are ergonomically designed, and have excellent resistance homes. Because of this, they are famously used in position that are subjected to dampness, chemical solvents as well as other potentially harsh product - caster china.

Furthermore, the material can additionally operate in extreme outside conditions, and is not impacted by solvents either. Wheels developed with pliable iron or actors iron improve the filling capacity of the item they are fitted with. They are temperature-resistant as well, use smooth mobility, and are not likely to get damaged or damaged regularly.

Caster Manufacturer for Dummies

, like Jumac Cans, generally have both Nylon 6 and also polypropylene casters (with zinc-coated bodies) in their profile. Caster wheels are additionally classified on the basis of their toughness rankings, which suggests their load capacities. On this basis, casters can broadly be separated under 3 heads: These can generally support weights in excess of 140 kgs, without any considerable mobility or mechanical issues - caster wheel manufacturer.

Weights in the array in between 70 kgs and also 140 kgs can be mounted on medium-duty casters. Prior to really placing on the load, it is always suggested to cross-check the wheel capabilities with the maker. As their name recommends, these wheels come with the least expensive load-bearing capability (normally, under 70 kgs).

The wheel wheels have actually limited maneuverability, contrasted to rotate wheels. The taken care of casters can only be rolled backwards and also forward and also as such, are not appropriate for certain applications.

Things about Caster Wheel Manufacturer

While kingpinless casters are normally more pricey than common swivel wheels, their shock-absorption and stress-resistance abilities are significantly higher. A specific kind of caster wheel (that need to be fluff and also dust-free) are needed for HDPE spinning containers.These tracks have really good traction, as well as they can be made use of with equivalent ease on both floor surface areas and also tracks. The high shock-absorption capability of pneumatically-driven wheels is derived from the air filled up in them. These wheels are readily available in both tubeless and tubed ranges. There are numerous scales (e.

As a regulation of thumb, metal casters are the hardest of them all followed by the plastic casters, and finally, the rubber casters. The firmness or gentleness of caster wheels directly influence their movements. Usually, the harder the wheel is, the reduced is their 'rolling resistance'. This, in turn, guarantees that moving the wheels at a consistent rate calls for less force.

As an outcome, softer wheels can function more 'quietly' than their harder counterparts. The size and size of wheel wheels likewise need to casters supplier be checked particularly when they are being fitted to rotating cans for smoother bit handling. Both the 'beginning resistance' and 'rolling resistance' figures are vice versa proportional with the wheel diameter and also width.

All About Caster Wheel Manufacturer

Due focus requires to be paid to the security aspect. Offered the significance of caster mount on the overall functionality and resilience of the product, a category can be done on its basis - caster china. Stem place, plate mount as well as bolt-hole place (stemless variety) are the typical types of installs made use of.Buyers likewise require to examine the measurements of the wheel stem, or ask the manufacturer regarding the very same. Not all wheel wheels have similar collections of functions.

Wheels can also be twin-wheeled in the housing. To get you require correct guidance. Depending upon the underlying applications, the wheel configuration differs as well (for both swivel casters and rigid wheels). The selection of caster wheel for bit cans must preferably depend on the flooring type at the rotating mills.

Report this wiki page